Categories

- Broadcast, Film and Audio 1072

- Construction and Mining 453

-

Electronics 1080

- Factory equipment - complete production units 98

-

Food processing machines 4629

- Bakery - Coating, paning and breading machines 66

- Bakery - dough dividers, moulders and sheeting machines 242

- Bakery - kneading machines 188

- Bakery - other machines 108

- Beaters / mixers / tumblers 282

- Brine injection machines 43

- Butchery - Bowl Cutters 66

- Butchery - cutters / slicers / choppers / portioning machines 395

- Butchery - mincers / grinders 141

- Butchery - slaughterhouses 33

- Butchery - stuffers 161

- Candy / Sweets machines - miscellaneous machines 222

- Candy / Sweets machines - simple / double twist wrapper 74

- Candy / sweets machines - cutting and wrapping machines 87

- Chocolate machines 197

- Coating pans 78

- Coffee roasters 154

- Complete biscuit or croissant production lines 63

- Complete bread production lines 66

- Complete pasta or pizza production lines 57

- Cookers 110

- Dairy - butter production, wrapping and portioning machines 14

- Dairy - cheese production, wrapping and portioning machines 67

- Dairy - cream separators 28

- Fryers 75

- Miscellaneous (food) 469

- Ovens - cooking tunnels 55

- Ovens - multi-deck / stoves / rotary ovens 104

- Pasteurisers 69

- Refrigeration - cold rooms / cold stores 48

- Refrigeration - cooling tunnels 71

- Refrigeration - ice cream machines 41

- Skinning / filleting machines 160

- Smokehouses 29

- Vegetable and fruit cutting, washing and blanching machines 387

- Wine, beer or alcohol making machines 180

-

Metal - Machine tools 11837

- Bar feeders 115

- Borers - deep hole drilling machines 58

- Borers - floor type boring machines 25

- Borers - floor type boring machines CNC 71

- Borers - table type boring machines 122

- Borers - table type boring machines CNC 137

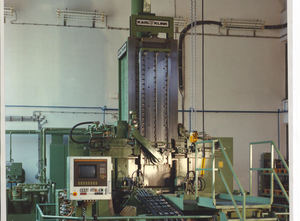

- Broaching machines 24

- Drilling - automatic/ CNC turret drilling machines 30

- Drilling - floor type drilling machines (column, pillar) 41

- Drilling - others (multispindle, column, pillar...) 31

- Drilling - radial drilling machines 125

- Edm - die sinking machines 168

- Edm - wire cutting machines 209

- Finishing - lapping / honing / vibratory deburring machines 67

- Finishing - others (washing / tumbling ) 30

- Gear machines - others (milling, testing, inspection..) 50

- Gear grinding machines 39

- Gear hobbing cnc machines 64

- Gear hobbing manual machines 69

- Gear shaping machines 43

- Grinding machines - cylindrical centerless grinders 140

- Grinding machines - cylindrical external / internal grinders 332

- Grinding machines - miscellaneous (crankshaft, sharpening, tool grinders ...) 214

- Grinding machines - surface grinders 487

- Lathes - 0 - 3000 mm 470

- Lathes - > 3001 mm - heavy duty lathes 234

- Lathes - Multispindle automatic lathes 422

- Lathes - Swiss type lathes 154

- Lathes - cnc lathes 1806

- Lathes - others 29

- Lathes - vertical turret lathes 75

- Lathes - vertical turret lathes with cnc 176

- Machining centers - 5 axis 527

- Machining centers - high-speed (18000+ rpm) 77

- Machining centers - horizontal 311

- Machining centers - palletized 174

- Machining centers - vertical 1905

- Milling - travelling column milling machines 95

- Milling - universal milling machines 361

- Milling - cnc bed type milling machines 294

- Milling - cnc universal milling machines 302

- Milling - miscellaneous machines 58

- Milling - portal / gantry milling machines 154

- Others 848

- Planing machines 13

- Rotary transfers 29

- Saws for metal - band saws 330

- Saws for metal - others (hacksaws, slitting saws, circular...) 160

- Shaping - vertical / horizontal shaping / slotting machines 41

- Spring machines - multislide / formers / coilers 20

- Thread rolling machines 62

-

Metal - Presses / Forging 1240

-

Metal - Sheet metal machines 4149

- Combining machines laser / punch 18

- Complete unwinding units 15

- Cutting machines - Laser 695

- Cutting machines - Plasma / gas 283

- Cutting machines - Waterjet 77

- Deburring machines 39

- Folding machines 80

- Leveling / straightening machines 70

- Notching machines 24

- Others sheetmetal machinery 137

- Plate rolling machines 150

- Plate rolling machines - 4 rolls 114

- Press brakes 230

- Press brakes cnc/nc 678

- Profile bending machines 127

- Punching machines / nibbling machines 69

- Punching machines / nibbling machines with CNC 296

- Shears - hydraulic guillotines 340

- Shears - mechanical guillotines 41

- Shears / guillotines CNC 156

- Slitting lines / Cut to length lines 73

- Tube bending machines 159

- Welding machines 207

- Welding positioners 70

-

Miscellaneous industrial equipment 3795

- Complete units 138

- Compressed-air plants 23

- Compressors 184

- Conveyors 151

- Cranes - Bridge cranes / hoisters 141

- Cranes - Tower cranes - gantry 32

- Dehydration and filtering 104

- Electricity - Generator sets 271

- Energy 44

- Forklifts - Diesel forklifts 32

- Forklifts - Electric forklifts 50

- Forklifts - Gas forklifts 34

- Glass machinery - Cutting - Edging 84

- Glass working machines - Bevelling 33

- Glass working machines - Insulating 31

- Glass working machines - Miscellaneous 79

- Glass working machines - washing - coating - printing 24

- Heat / surface treatment 46

- Industrial boilers 125

- Industrial ovens 116

- Liquids cooling / Chillers 162

- Measure - controls - Miscellaneous 42

- Measure - controls - Profile projectors 54

- Measuring units 191

- Miscellaneous 524

- Miscellaneous Handling - Lifting 84

- Pallet racks - storage units - Kardex 51

- Public works - Miscellaneous 57

- Pumps and industrial pumping systems 140

- Robots 580

- Spray booths / painting units 76

- Stone industry equipment - marble and granite 32

- Vacuum cleaning units 48

-

Packaging - Conditioning 6714

- Bagging machines - Horizontal - Flowpacks 279

- Bagging machines - Vertical - Sachet machines 245

- Baling presses - waste compactors 22

- Blister machines 190

- Bundlers 53

- Capping machines - cappers - crimping machines 367

- Cartoning machines / cartoners - Horizontal 272

- Cartoning machines / cartoners - Vertical 98

- Case packers 314

- Cellophane / overwrapping machines 129

- Checkweighers 165

- Feeders - scales - sorting machines 363

- Filling machines - Bottling equipment 307

- Filling machines - Food industry 162

- Filling machines - Tube fillers 414

- Filling machines - Various equipment 457

- Filling machines - Vials / ampoules fillers 93

- Inspection machines 125

- Labellers 677

- Metal detectors 129

- Miscellaneous packaging machines 421

- Multihead weighers 74

- Palletizers - palletizing robots 69

- Shrink wrap machines / Sealers 285

- Shrinking tunnels 55

- Strapping machines 50

- Stretch wrapping machines 102

- Taping machines 33

- Tea / Coffee bag machines 37

- Thermoforming - Form, Fill and Seal, FFS lines 535

- Tray sealers 188

-

Pharmaceutical - Chemical 4087

- Mills 218

- Miscellaneous pharmaceutical / chemical machines 291

- Mixers - Multishaft and Planetary Mixers 529

- Mixers / Blenders - Powder solid 162

- Mixers / Homogenizers - Liquid cream 227

- Pharmacy / medical - complete production lines 64

- Tablet coating machines 59

- Tablet presses - rotary / rotary compacting presses 173

- Tablet presses - single-punch / eccentric / single station press 128

- Tanks - boilers - melting tanks 397

-

Plastic - Rubber 3223

-

Printing machines 3012

- 3D Printer 143

- Binding - gang stitchers / sewing machines 23

- Binding - gatherers / collators 125

- Binding - perfect binders / thermal binders 81

- Binding - saddle stitchers 86

- CTP computer to plate 71

- Carton and board converting machines 29

- Case making machines 38

- Die-cutters / Embossers / Hot foil 176

- Digital printing presses 269

- Envelopes - Insertion / Printing 87

- Flexo printing machines 84

- Folders - gluers / staplers / wire binders 307

- Label printing machines 98

- Laminators 100

- Letterpresses - cylinders / platens 14

- Offsets 1 colour 37

- Offsets 2 colours 90

- Offsets 4 colours 128

- Offsets 5 colours 79

- Offsets 6 colours 16

- Offsets 8 colours and more 21

- Others - post press machines 107

- Others - press and printing 124

- Paper and board machines - Others 55

- Paper and board machines - Sheeters / cut size 37

- Paper and board machines - Winders / rewinders / unwinders / slitters 73

- Plotters - Large format inkjet 158

- Screen printing equipment 90

- Trimmers - Guillotines / Cutters 198

- Trimmers - Three knife 11

- Web continuous printing presses 46

-

Textile machines 1468

- Complete plants/production units 31

- Cutting - automated cutting machines 173

- Cutting - spreading machines 32

- Embroidery machines - large orders embroidery machines 18

- Embroidery machines - one head / multi-heads 112

- Finishing - Washing / Steaming / Ironing machines / Folding machines 88

- Finishing - dryers 27

- Finishing - dyeing machines 55

- Finishing - shearing machines 6

- Finishing - stenters 17

- Knitting - circular knitting machines 83

- Knitting - flat knitting machines 82

- Knitting - knitting machines for socks / tights 56

- Miscellaneous used textile machines 126

- Printing - calenders 43

- Printing - rotary textile printers 64

- Printing - textile presses 39

- Sewing machines / making - automatic machines 118

- Special textile machines - equipments for non weaved textile 43

- Special textile machines - unrolling & inspection machines 21

- Spinning - carding machines 26

- Spinning - preparation 10

- Spinning - spinning machines 25

- Spinning - twisting / assembling 28

- Spinning - winders 44

- Weaving - looms 38

- Weaving - looms with jacquard 34

- Weaving - sectional warping machines 23

-

Woodworking machines 2283

- Boring, drilling and dowel inserting machines 66

- Briquetting machines 19

- Brushing machines 16

- Drying - kilns, ovens 24

- Dust collectors / exhausters 39

- Edgebanders - double sided 49

- Edgebanders - single sided 231

- Finger Joint machines 20

- Gluing machines 20

- Guillotines for veneer 22

- Miscellaneous wood machinery 117

- Moulders - multihead 151

- Moulders - spindle moulding machines 21

- Planing machines / Jointers 55

- Routers 69

- Sanding - Wide belt sanders 142

- Sanding / grinding - others 43

- Saws - band saws 30

- Saws - cross-cut optimizing saws 44

- Saws - multi-blade saws 83

- Saws - other (mitre, cut off) 39

- Saws - panel saws 115

- Saws - sliding table saws 45

- Spraying machines 52

- Tenoning machines 50

- Wood CNC machining centres 311

- Wood CNC machining centres - 5 Axis 44

- Wood CNC machining centres - Doors and windows 36

- Wood Presses 116

- Wood chipping machines 69

- Wood combined machines 10

- Wood lathes 14

- Wood milling machines 45

- Woodworks plant and complete wood units 55

Машини за протягане

Машини за протягане

Protahovací stroje

Protahovací stroje

Brocheringsmaskiner

Brocheringsmaskiner

Räummaschinen

Räummaschinen

Μηχανές σπάσιμου

Μηχανές σπάσιμου

Broaching machines

Broaching machines

Brochadoras

Brochadoras

Brocheuses

Brocheuses

Strojevi za provlačenje

Strojevi za provlačenje

Nyújtógépek

Nyújtógépek

Brocciatrici

Brocciatrici

Prapjovimo mašinos

Prapjovimo mašinos

Brootsmachines

Brootsmachines

Przeciągarki

Przeciągarki

Brochadeiras

Brochadeiras

Mașini de broșat

Mașini de broșat

Прошивочные станки

Прошивочные станки

Mašine za provlačenje

Mašine za provlačenje

Broschmaskiner

Broschmaskiner

Broş tezgahları

Broş tezgahları

Italy

Italy

USA

USA

Sweden

Sweden

France

France

Turkey

Turkey

Spain

Spain

Germany

Germany

United Kingdom

United Kingdom

Croatia

Croatia

Belgium

Belgium